2023

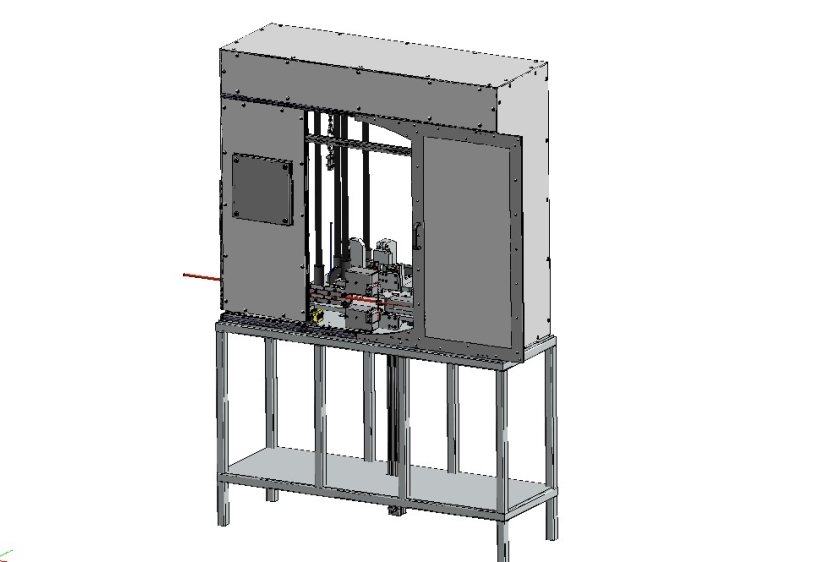

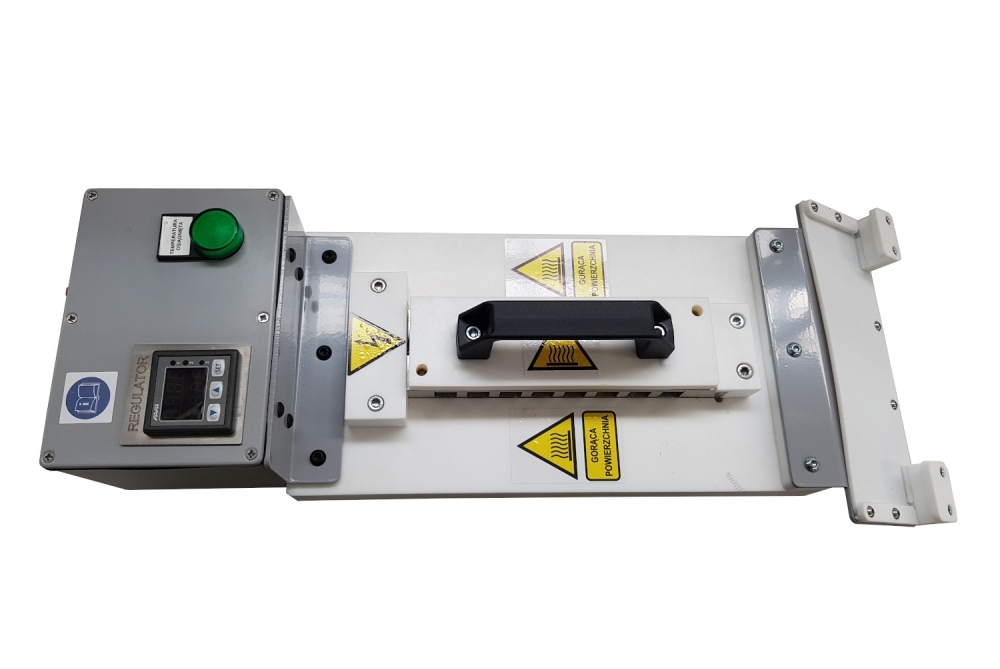

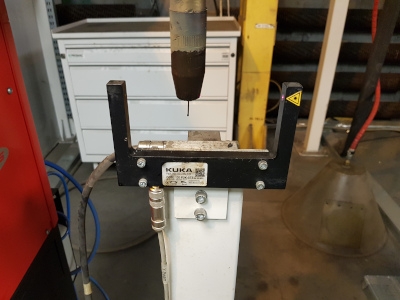

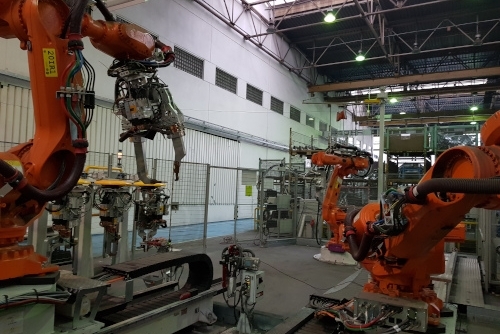

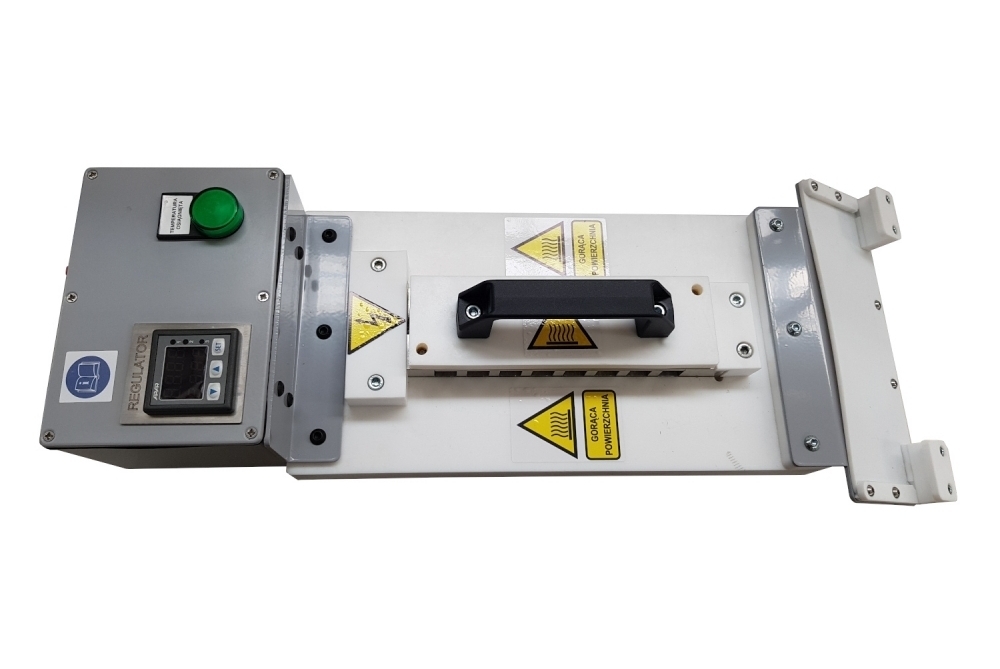

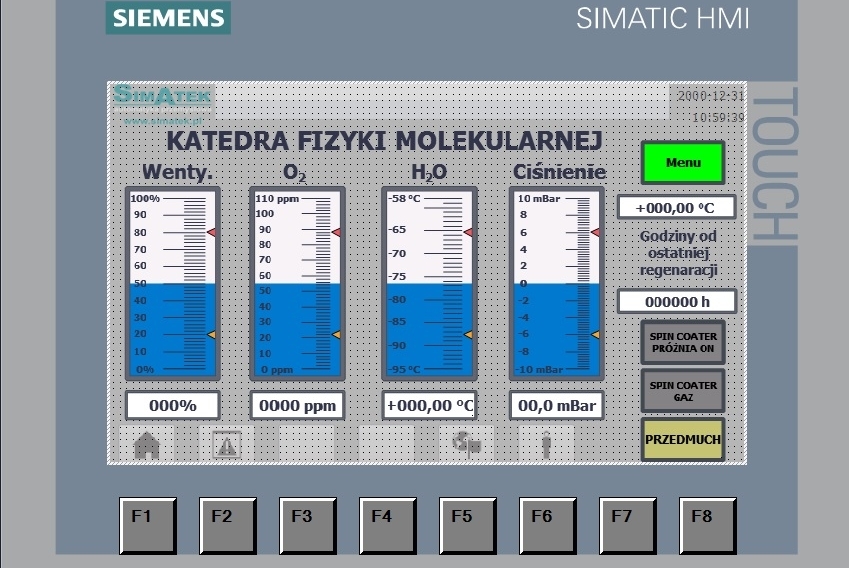

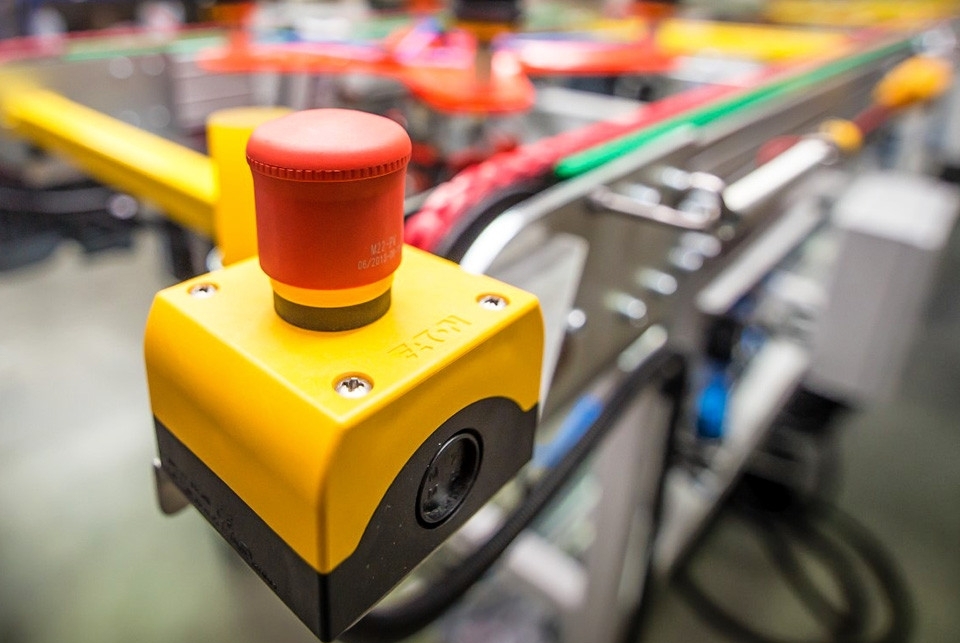

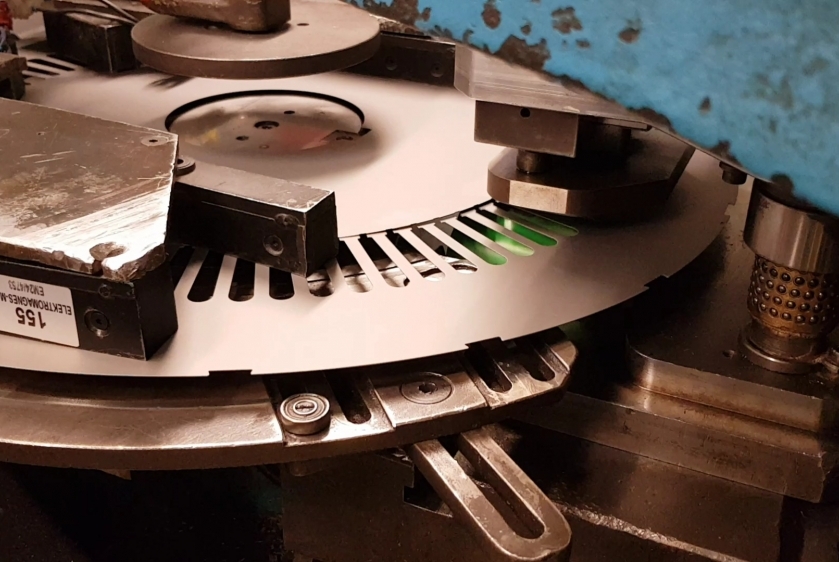

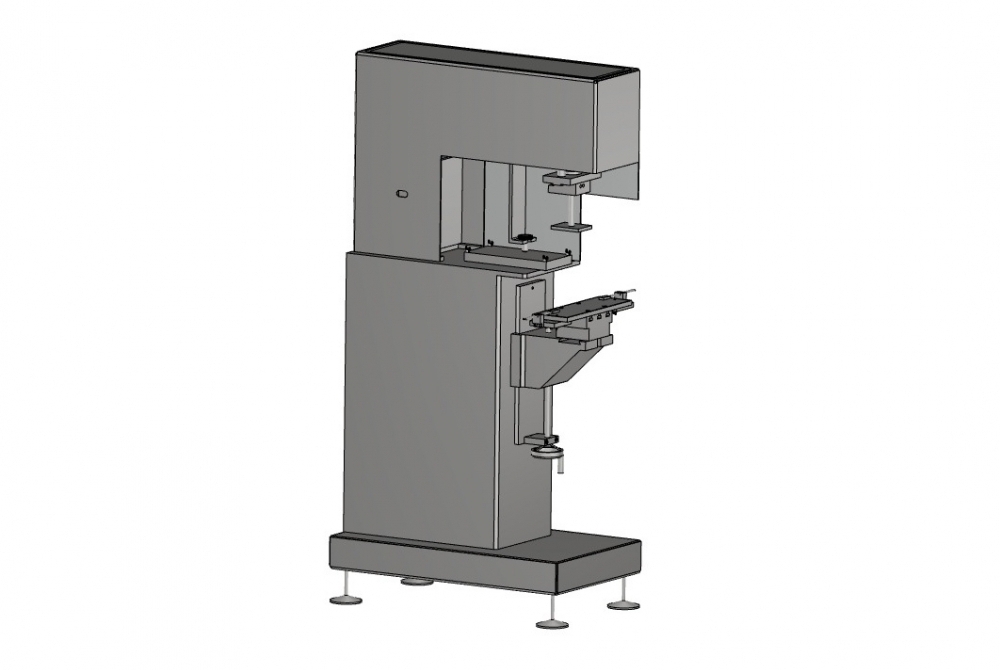

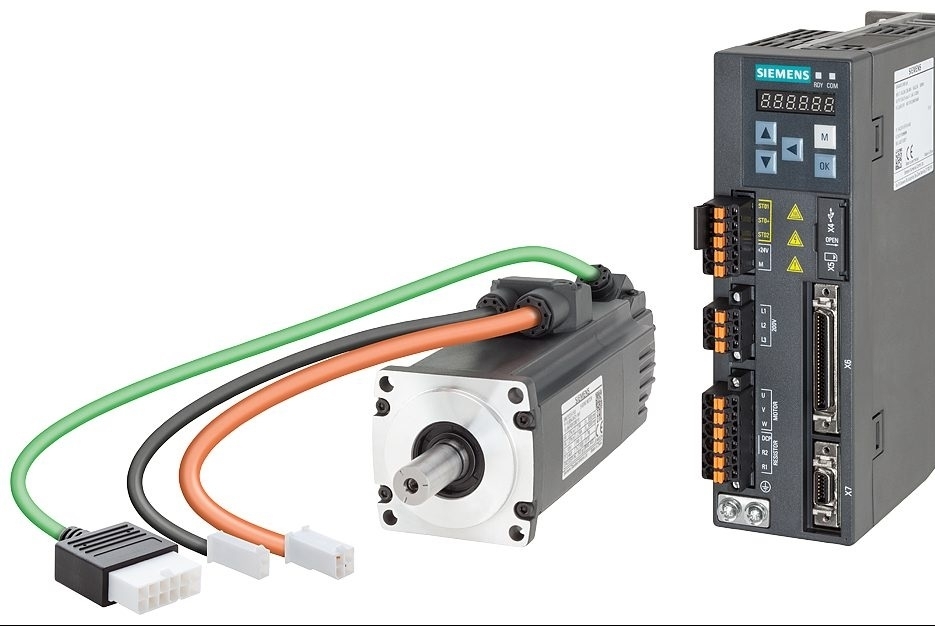

Modernization of the safety system, conveyor systems, packaging

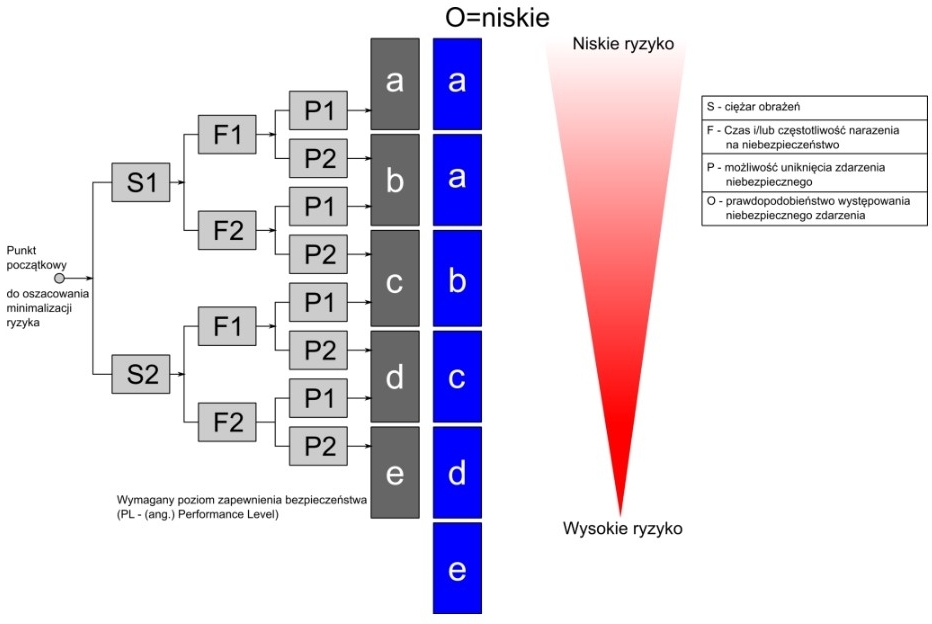

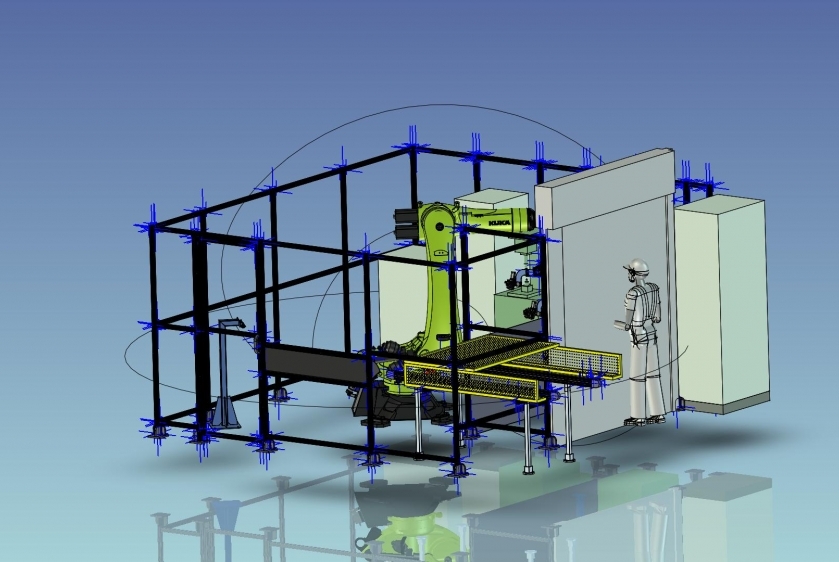

Adapting the machines to health and safety requirements was based on an audit of the production lines. Creating a report and then, based on this document, modernizing machines for safety